PRODUCT05

Heat Exchanger (KAJIWARA Heater)

| Applications | Heater for generator engine fuel oil |

|---|---|

| Industry | Steel mills / Garbage incineration plants / Biomass power plants / Chemical plants |

| Keywords. | # air pollution # work environment # health |

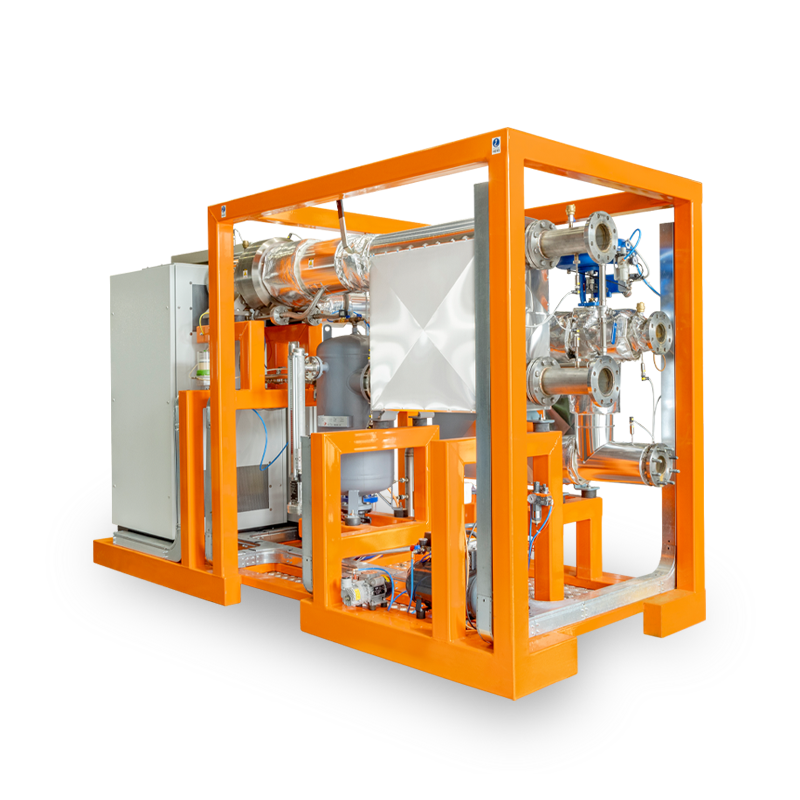

Integrated production

In January 2004, we took over the sales rights from Aalborg Industries, Inc. and also accepted engineers transferred from the company. Thus we started operation as an integrated manufacturer handling design, production, and sales.

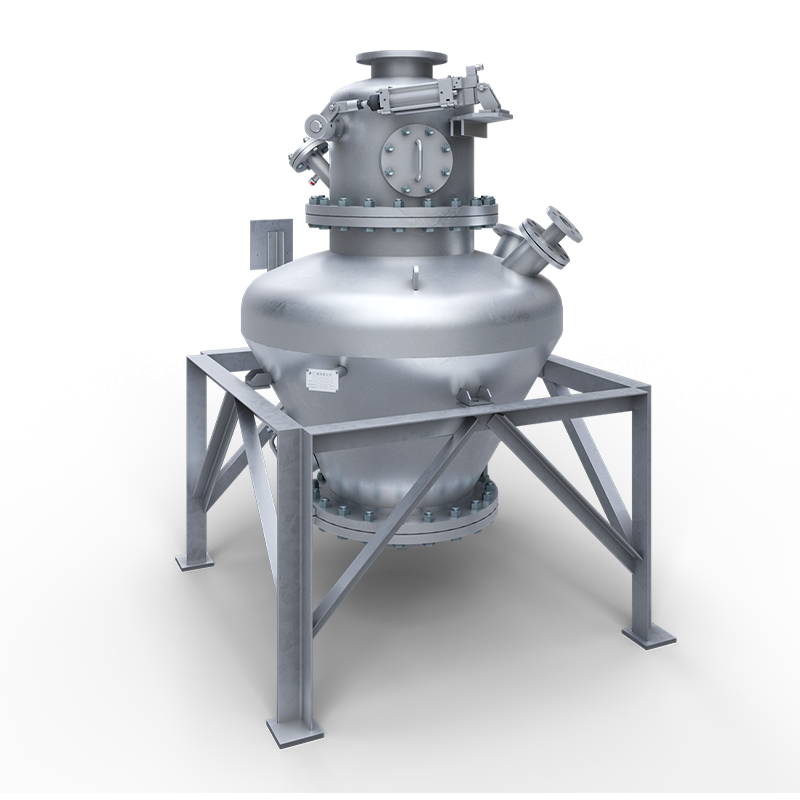

Classification

Depending on the shape of the heating surface, they are classified into “pin tube type” and “coil tube type”.

What is the KAJIWARA Heat Exchanger? (History since it was developed)

Application of KAJIWARA heaters (What are the applications?)

Application

- 1.Main Engine Fuel Oil Heater

- For good injection of Fuel oil to main engine, it is required to keep the fuel oil viscosity between 10 – 15cst at main engine inlet.

To reduce the fuel oil viscosity, it is required to increase the temperature.

Example of fuel oil temperature at heater outlet:

380cst at 50DEG Fuel oil: 135 – 140DEG at heater outlet.

500cst at 50DEG Fuel oil: 145 – 150DEG at heater outlet.

- 2.Generator Engine Fuel Oil Heater

- Same as Main Engine F.O. Heater

- 3.Purifier Fuel Oil Heater

- Water or foreign material to be removed from Fuel Oil by Purifier before supplied to Main Engine or Generator Engine.

Purifier remove foreign material and water which is heavier than oil by means of centrifugation.

It is required to keep the Fuel Oil temperature lower than 100DEG to avoid water evaporation during the Purifier operation.

Oil inlet temperature of Purifier F.O. Heater is about 60DEG which is almost same as F.O. Temperature in the F.O. settling tank.

Oil outlet temperature of Purifier F.O. Heater is about 95 – 98DEG.

Purified F.O. is stored in the service tank.

- 4.Purifier Lubricating Oil Heater

- Lubrication oil which is used for Main Engine or Generator Engine also required to purify from foreign material like as metal chips from engine cylinder etc.

L.O. temperature at oil heater inlet: about 45-50DEG

L.O. temperature at oil heater outlet: about 90 – 95DEG (up to kind of L.O.)

- 5.Boiler Fuel Oil Heater

- Boiler fuel oil viscosity to be lower than 50cst at burner inlet for good combustion.

Fuel oil temperature at heater outlet is required to be heated up to 110 – 125DEG.

As purified Fuel oil is not required for boiler F.O, Fuel oil from settling tank is supplied which temperature is about 60DEG.

- 6.Shifter Fuel Oil Heater

- In traditional system, Fuel oil in the F.O. storage tank is kept it’s temperature by means of base heater. (Steam heating tubes are installed at tank bottom.)

Once the base heater tubes are damaged, it is very difficult to repair as the tank is filled by F.O. (Tank to be empty for repair or renewal work)

Recently shifter F.O. heater is adopted instead of base heater.

Fuel oil in the tank is supplied to Shifter F.O. heater by transfer pump then the heated F.O. is returned to the tank.

F.O. inlet temperature to Shifter F.O. heater is same as tank temperature of ab.50DEG and heated up to ab. 90DEG.

- 7.Thermal oil heater

- In case of thermal oil is used instead of steam as heating medium, Coil tube type heater is recommended.

(Pin tube type is designed only for steam heating system.)

Thermal oil outlet nozzle is located at the upper side of the heater for the purpose of good air venting.

- 8.Industrial use Heat exchanger

- KAJIWARA heat exchanger is also used for Land use like as

Diesel generator Fuel oil heater

Purifier Fuel & Lub. Oil heater

Thermal power plant boiler F.O. heater.

- 9.Tank suction heater (Industrial use)

- Tank suction heater is installed to the side wall of C-heavy oil tank.

As the heater is installed at suction side of the transfer pump, it’s oil side pressure drop to be lower than the water head of the tank.

- 10.Other fluid than oil

- Coil tube type heat exchanger is possible to change the casing &/or coil tube material to Stainless steel (SUS316L) instead of carbon steel.

By using the stainless steel, other corrosive fluid like as water can be treated as heating and / or heated medium.

- 11.Marine Gas Oil (MGO) Cooler

- Along with the requirement of environmental pollution reduction, Marine Gas Oil (MGO) is used as Ship’s Fuel.

MGO to be cooled down to increase it’s viscosity to ab. 1.5 – 2cst.

Coil tube type heat exchanger with stainless steel coil tube (BNR type) is used as MGO Cooler.

But, cooling medium is limited to only Fresh water. (Sea water could not be used for BNR type)

Spiral shaped coil tube is difficult to clean up the tube inside once contaminated with marine life like as shellfish kind.

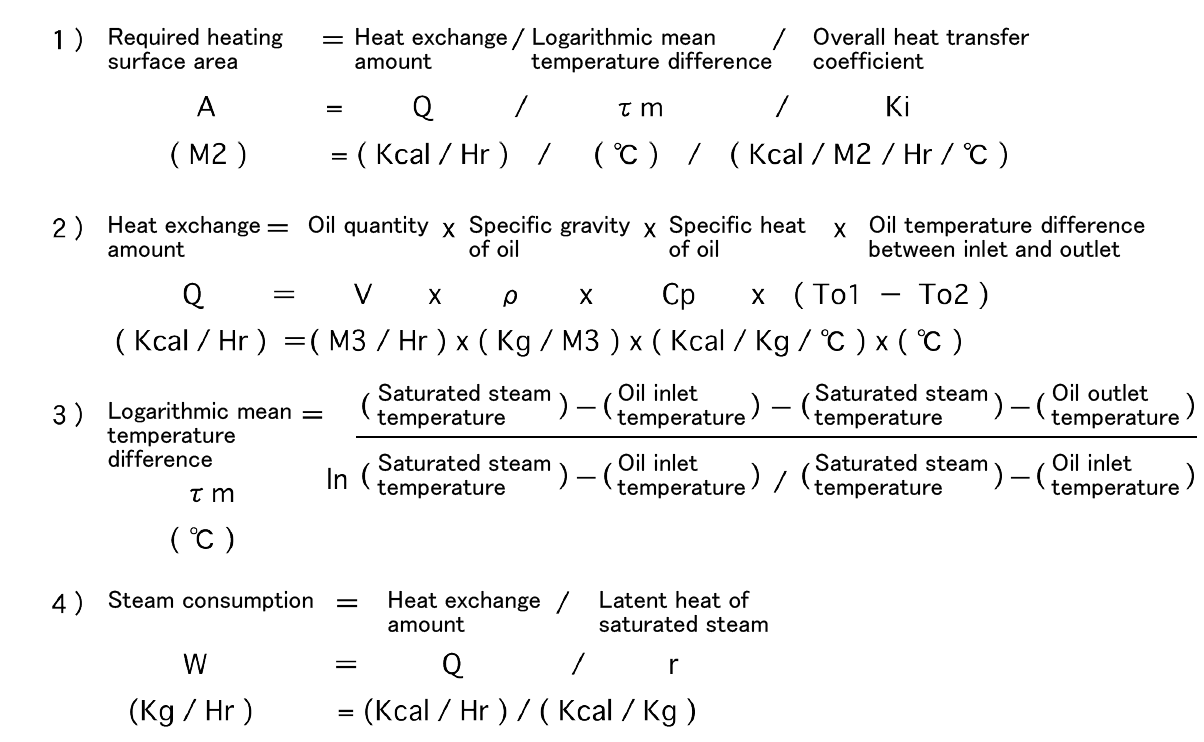

Basic calculations of heat transfer

PRODUCT LIST