PRODUCT01

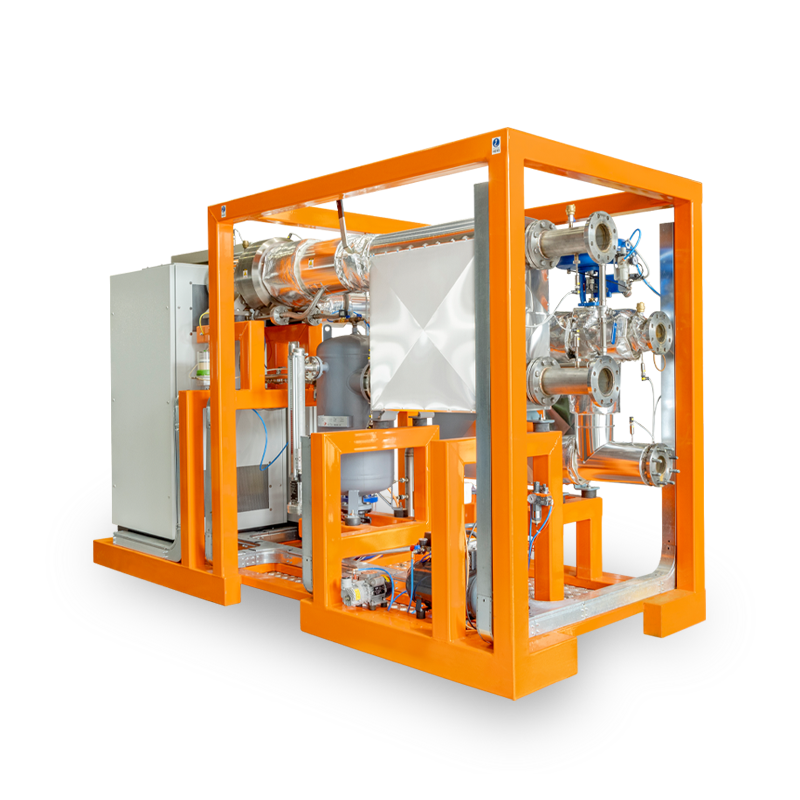

KJ Regenarative Thermal Oxidizer (RTO)

- Removal efficiency of over 99%! The exhaust gas treatment equipment capable of VOC and odor control.

- Energy-saving thermal oxidizer with reduced fuel consumption and CO2 emissions due to high heat exchange efficiency.

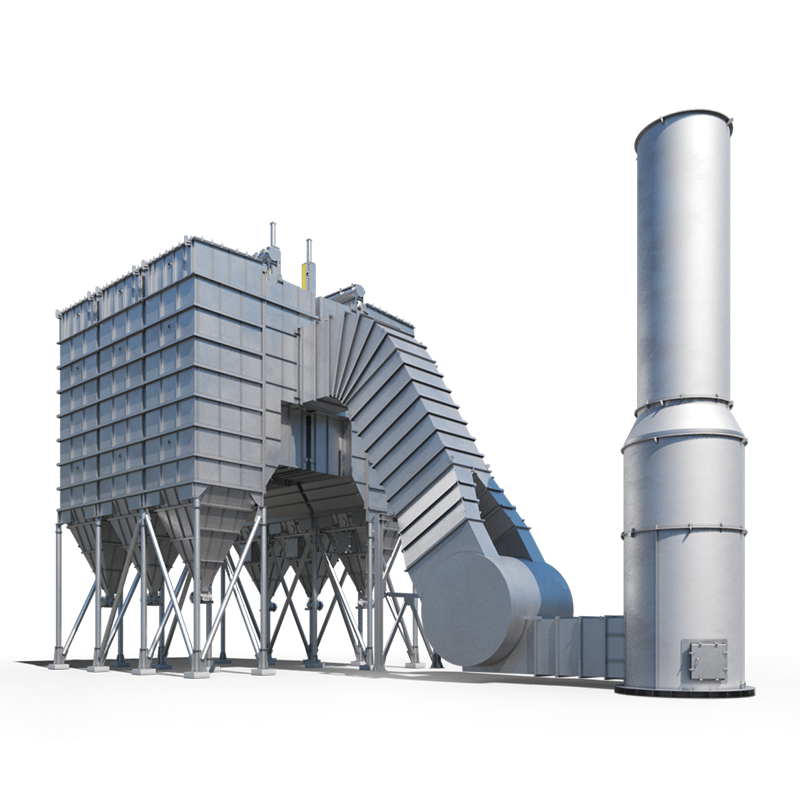

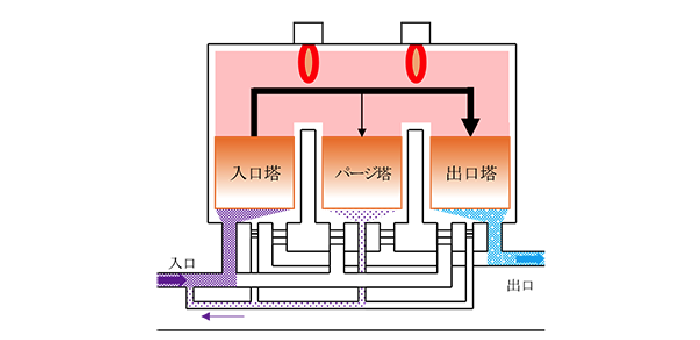

Equipment structure (3 canisters)

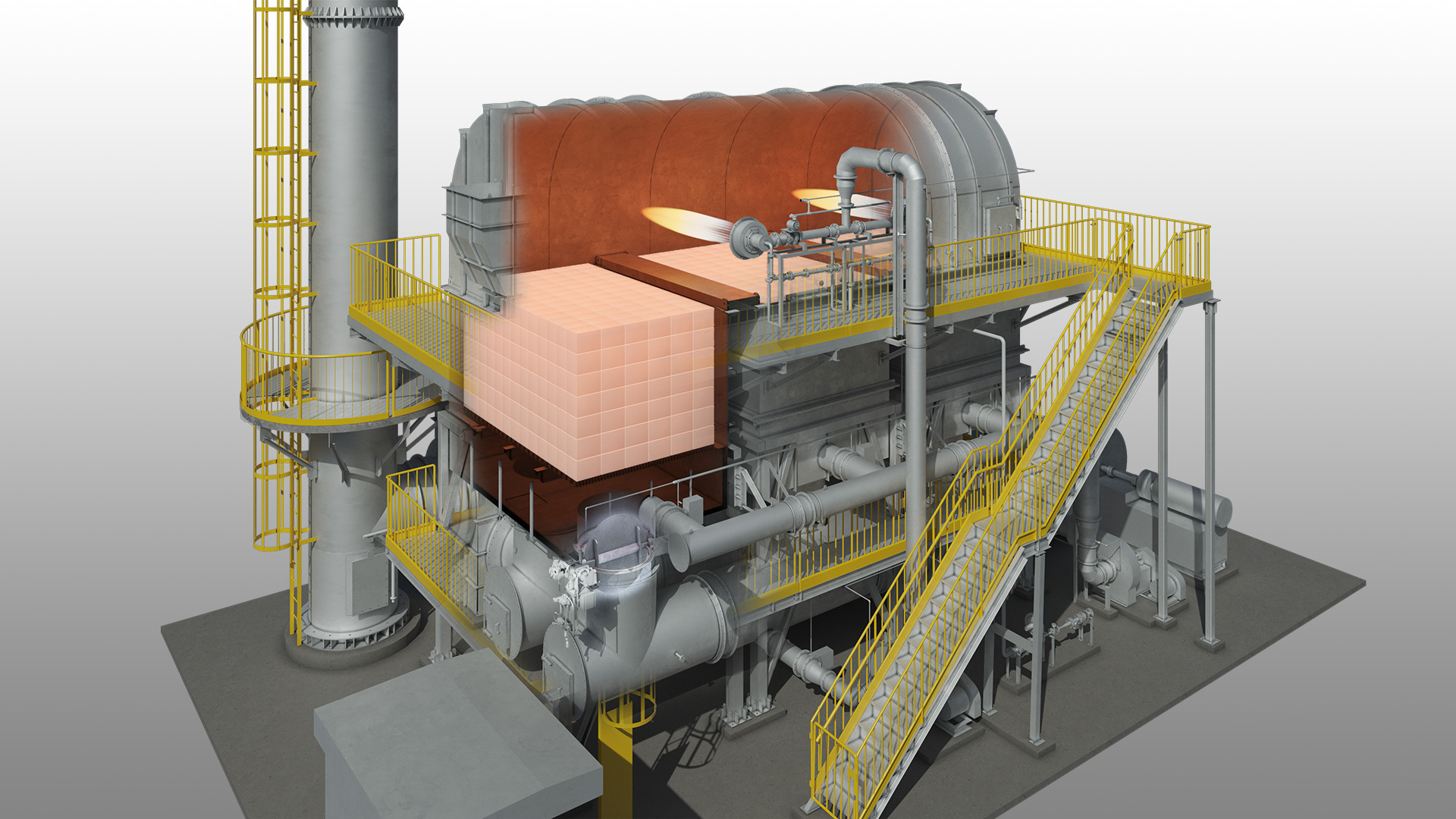

- ① Process gas is heated to high temperature and oxidized and decomposed.

- ② Optimally controlled by the Retention chamber temperature, and self- combustion operation is performed when the solvent concentration is high.

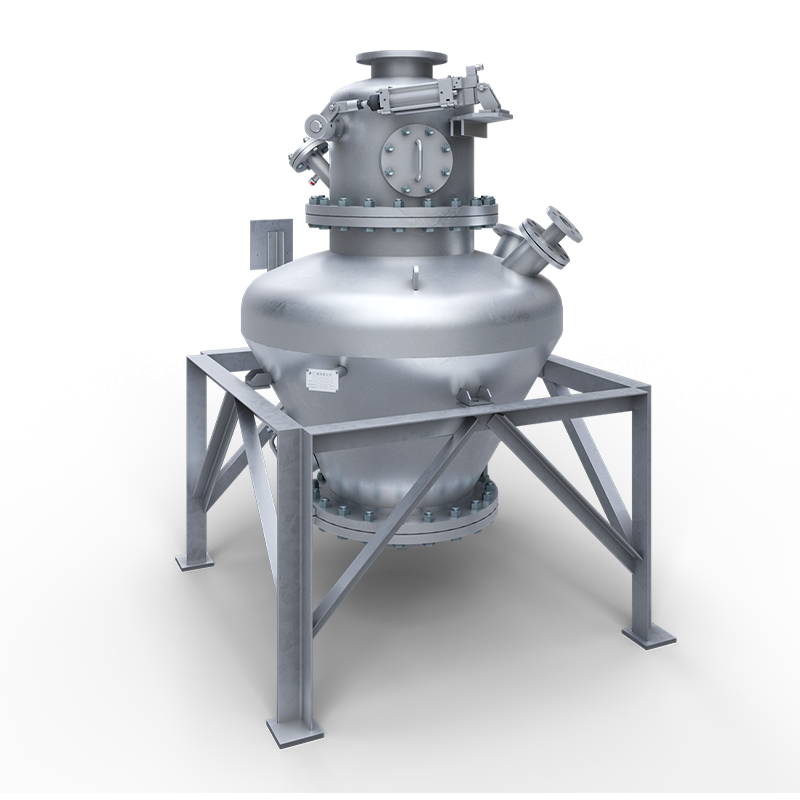

- ③ “Heat storage layer”: High heat exchange efficiency is achieved by using ceramic heat reservoir.

- ④ “Switching dampers”: The gas flow in each canister is controlled by switching the inlet and the outlet.

Switching the dampers at regular intervals enables the system to operate stably and optimize fuel consumption and heat storage.

We also offer heat recovery systems using steam, hot air, or heat medium oil, as well as affordable two-canisters RTO.

The process gas is preheated as it passes through the first canister and VOCs and odors are oxidized and decomposed in the retention chamber. After decomposition, the heat is supplied to the heat storage layer as the gas passes through the third canister, and it is exhausted after being cooled down to near the inlet temperature.

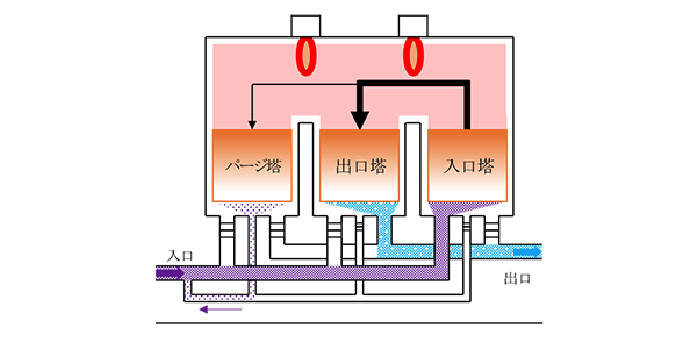

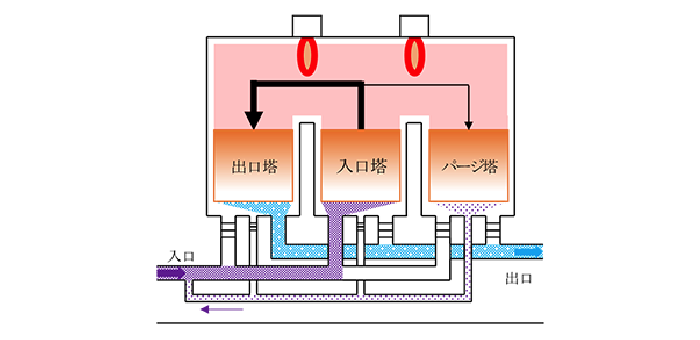

As the heat storage layer of the third canister has stored sufficient heat in Operation 1, the damper switchs the gas flow and the canister changes its role from the inlet to the outlet.

The first canister, which was the inlet in operation 1, returns unprocessed gas to the upstream of the system at the moment of the switchover to prevent odor emissions. (Purge canister)

The first canister, which was the inlet in operation 1, returns unprocessed gas to the upstream of the system at the moment of the switchover to prevent odor emissions. (Purge canister)

Repeating the above operation cyclically at regular intarevals enable the system to operate stably.

Features

- Capable of handling a wide range of VOCs & odors

- Capable of handling large air volumes of 1,000 Nm3/min or more

- High heat exchange efficiency significantly reduces fuel consumption and CO2 emissions

- Clean bake-out system that completely prevents odor emissions

- The waste heat recovery of steam, heat media, hot air, etc.

- Maintenance such as periodic inspections and other supports after delivery (optional)

Corresponding process

- Carbon Fiber related procrss: Carbon Fiber, Composite Materials

- Printing related process: Gravure printing, laminating, wallpaper printing

- Adhesive related process: film, adhesive tape, printed circuit board

- Coating related process: Color steel sheet and metal can printing

- Also applicable to various other VOC and odor processes

PRODUCT LIST